Safety is the Only Metric That Matters: No Plastic or Fiberglass!

In the storm shelter industry, there are trends, and there are truths.

Trends come and go. New materials enter the market, promising lighter weights, cheaper shipping, and easier installation. We see ads for “space-age” polymers and fiberglass shells that claim to be the future of tornado protection.

But at Oklahoma Shelters, we deal in truths.

The truth is that Oklahoma weather is violent. The truth is that our soil is aggressive. And the truth is that when an EF-5 tornado is grinding across the landscape, “trendy” materials are not what you want standing between your family and the storm.

We are often asked why we don’t offer fiberglass or polyethylene (plastic) shelters. It would certainly be easier for us. They are light. They are easy to truck around. We could sell them cheaper.

But we won’t do it.

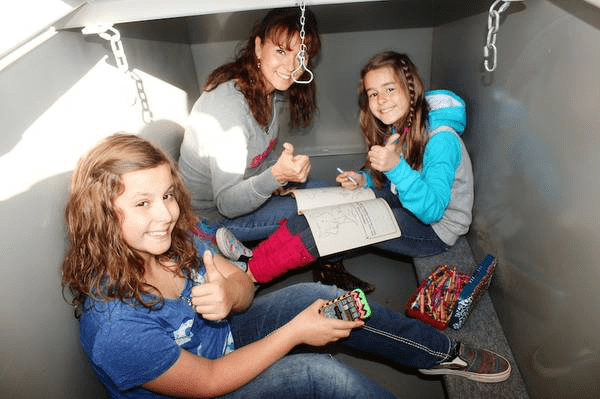

We refuse to sell a product that we wouldn’t put our own mothers in. Our commitment is to steel and concrete. This article explains exactly why we have taken a hard stance against plastic and fiberglass underground shelters, and why you should too.

The “Boat” Effect: Understanding Buoyancy

The number one reason we avoid lightweight materials is simple physics.

Plastic shelters are essentially boats.

If you take a watertight, lightweight plastic tub and bury it in the ground, you are conducting a physics experiment. As long as the ground is dry, it stays put. But this is Oklahoma. We don’t just get wind; we get torrential rain.

The High Water Table Problem

In many parts of Oklahoma, the water table is high. When we get spring storms, the ground saturates quickly. The soil turns into a heavy, fluid mud.

Archimedes’ principle states that an object immersed in a fluid is buoyed up by a force equal to the weight of the fluid displaced by the object.

- Concrete: Concrete is denser than water/mud. It sinks. It stays where you put it.

- Steel: Steel is heavy, and our underground garage units are anchored directly into the slab.

- Plastic/Fiberglass: These are much lighter than the mud surrounding them.

The Pop-Out Phenomenon

We have seen it happen. A homeowner buys a fiberglass shelter. A heavy rain comes. The hydrostatic pressure pushes up on the bottom of the lightweight shelter. Because the shelter doesn’t have the mass to counteract this force, it “pops” out of the ground.

It might rise just a few inches, snapping the plumbing or electrical lines running to it. Or, in severe cases, it can pop completely out of the hole, rolling across the yard like a cork.

To prevent this, installers have to pour concrete around the plastic shelter to weigh it down. Our logic is simple: If you need to pour concrete to make the shelter safe, why not just buy a concrete shelter in the first place?

Oklahoma Clay vs. Rigid Plastic

If you have lived here long, you know about our red clay. It is notorious among builders and foundation experts.

Oklahoma clay is “expansive.”

- When it gets wet: It swells and expands with tremendous force.

- When it dries: It shrinks and cracks.

This constant expansion and contraction exerts massive side-pressure on anything buried in it.

The Brittleness of Fiberglass

Fiberglass is strong in tension, but it can be brittle. Over time, as the ground shifts and squeezes against the walls of a fiberglass shelter, the material fatigues.

If the clay pushes hard enough, fiberglass can crack.

- A crack in a storm shelter is a disaster. It lets in water. It lets in snakes and spiders.

- Worse, under the impact of debris, a pre-stressed, brittle material is more likely to shatter than to deform.

The Flexibility of Steel

We use steel because it is “ductile.” If the ground shifts, steel can flex slightly without losing its structural integrity. If a heavy object hits it, steel might dent, but it rarely shatters. It absorbs energy.

Concrete, while rigid, relies on sheer mass and thickness (4 inches or more) to resist these soil pressures, something a thin fiberglass shell cannot compete with.

Fire Resistance: A Critical Overlooked Factor

Tornadoes are the primary threat, but they aren’t the only one.

Often, tornadoes damage gas lines. They knock down power lines. Fires can and do happen in the aftermath of a storm. Furthermore, many people use their storm shelters to store emergency supplies, including fuel or chemicals.

Material Flammability Matters.

- Fiberglass/Plastic: These are petroleum-based products. While many are treated with fire retardants, they can still melt, warp, or burn under intense heat. If debris piles on top of your shelter and catches fire, a plastic hatch or shell is a liability.

- Steel/Concrete: These are non-combustible. They do not burn. They do not melt until temperatures reach thousands of degrees—far hotter than a typical house fire.

According to FEMA P-320, the gold standard for residential safe rooms, the structure must be capable of protecting occupants from wind-borne debris. While some composite materials pass the impact test, we believe the added fire resistance of steel and concrete provides a necessary second layer of safety.

Impact Resistance: The “Eggshell” Theory

The main job of a shelter is to stop debris. We aren’t talking about small branches. We are talking about a 2×4 timber hurled at 100 mph.

The Test: The Texas Tech National Wind Institute performs the debris impact tests that set the industry standard (ICC 500). They shoot a 15lb 2×4 cannon at the shelter.

While high-end fiberglass can pass this test, there is a difference in how it passes.

- Steel: When steel is hit, it deflects. It might bend inward, but the metal remains a cohesive sheet. It stretches.

- Fiberglass/Composites: These materials are layers of cloth and resin. Under extreme, repeated impacts (like a house collapsing on top of it), there is a risk of “delamination.” The layers can separate. The material can fracture.

We prefer the peace of mind that comes with a material that bends rather than breaks.

Installation and Anchoring Issues

Because plastic shelters are so light, they rely entirely on their anchoring system to stay in the ground.

If the installer cuts corners—if they don’t pour enough concrete around the base, or if they use cheap straps—the shelter is unsafe.

Our Steel & Concrete Process:

- Garage Shelters: Our steel garage shelters are installed flush with the slab. They are cemented in and anchored. The surrounding slab acts as a shield.

- Concrete Shelters: These weigh thousands of pounds. Gravity is the anchor. There are no straps to rot. There are no bolts to rust out. The physics of the shelter itself keeps you safe.

We control every step of the installation. By using heavy materials, we remove variables. We don’t have to worry if the “ballast” was done correctly, because the shelter is the ballast.

The Longevity Question

A storm shelter is an investment in your home. It adds value to your property.

Plastic Degrades. Even underground, plastics can degrade over decades. If any part of the shelter is exposed to UV light (like the door or hatch), it can become brittle and chalky.

Steel and Concrete Endure.

- Concrete: Look at the Roman Pantheon. Concrete lasts. Our concrete shelters are reinforced and sealed. They will likely outlast the house they are sitting next to.

- Steel: We coat our steel shelters in coal tar epoxy or powder coating to prevent corrosion. A properly maintained steel shelter is a permanent addition to the home.

When you sell your home, a potential buyer looks at a steel or concrete shelter and sees “solid.” They look at a plastic shelter and wonder if it’s cracked or if it’s going to float away.

Why We Stick to What Works

At Oklahoma Shelters, we aren’t against innovation. We use the latest laser-cutting technology for our doors. We use advanced hydraulic lifts. We use the best weather-stripping and locking mechanisms available.

But when it comes to the shell—the thing that keeps the crushing weight of a house off your children—we don’t experiment.

We stick to the materials that have proven themselves in Moore, in Joplin, and in El Reno.

- We use Steel.

- We use Concrete.

- We do not use Plastic.

We sleep better at night knowing that. And we think you will too.

For more information on the testing criteria for storm shelters, you can visit the Texas Tech National Wind Institute. They are the authority on wind science and debris impact.

Your Safety is Non-Negotiable

Don’t settle for a plastic tub. Don’t risk your investment popping out of the ground after a heavy rain.

Choose the strength of steel. Choose the durability of concrete. Choose the company that puts Oklahoma families first.

Ready to get serious about safety?

Call Oklahoma Shelters today at (405) 367-7901. Let us give you a free consultation and show you the difference real quality makes.

[REQUEST YOUR FREE QUOTE HERE]

People Also Ask (PAA) for Oklahoma Shelters

1. Do fiberglass storm shelters float? Yes, fiberglass and plastic storm shelters are naturally buoyant and can float if not properly anchored. In areas with high water tables or heavy rainfall, hydrostatic pressure can push these lightweight shelters out of the ground, potentially damaging plumbing or electrical lines and compromising the structure’s stability.

2. Why are concrete storm shelters better than plastic for Oklahoma soil? Concrete storm shelters are superior for Oklahoma soil because their immense weight counters the state’s expansive red clay and high water tables. Unlike plastic, which can shift or pop out due to soil movement and hydrostatic pressure, concrete uses gravity to remain stable and secure without relying on straps or extra ballast.

3. Are plastic storm shelters fire resistant? No, most plastic and fiberglass storm shelters are made from petroleum-based materials that can melt, warp, or burn when exposed to high heat. In contrast, steel and concrete shelters are non-combustible, offering essential protection if a tornado causes secondary fires from ruptured gas lines or downed power cables.

4. Can fiberglass storm shelters crack underground? Yes, fiberglass shelters can crack due to the pressure exerted by expansive clay soil. As the soil swells with moisture and shrinks when dry, it puts immense side-pressure on the shelter walls. Fiberglass is brittle and can fatigue or fracture under this stress, whereas steel is ductile and flexes without breaking.

5. Which is safer: steel or fiberglass storm shelters? Steel storm shelters are generally considered safer because they are ductile and absorb energy from debris impacts without shattering. Fiberglass can be brittle and runs the risk of delamination or cracking under repeated heavy impacts or long-term soil pressure, whereas steel deflects debris and maintains structural integrity.

6. Do plastic storm shelters degrade over time? Yes, plastic and fiberglass materials can degrade over time, especially if exposed to UV light or extreme temperature fluctuations. This degradation can lead to brittleness and a chalky appearance. Steel and concrete shelters, when properly coated and sealed, are designed to last for decades without losing structural strength.

7. Why do some storm shelters pop out of the ground? Storm shelters pop out of the ground due to the Archimedes’ principle of buoyancy. If a shelter is lighter than the water-saturated soil displacing it (like a plastic or fiberglass unit), and it is not sufficiently anchored with heavy concrete ballast, the groundwater pressure will force it upward like a boat.

8. Do fiberglass shelters pass the FEMA debris impact test? While some high-end fiberglass shelters can pass FEMA and ICC 500 debris impact tests, the material reacts differently than steel. Fiberglass is a composite that may delaminate or fracture upon severe impact. Oklahoma Shelters recommends steel or concrete because they offer superior durability and fire resistance beyond just the initial impact rating.

9. Can I install a storm shelter in Oklahoma red clay? Yes, but you must choose the right material. Oklahoma red clay is highly expansive, meaning it swells significantly when wet. Heavy, rigid structures like reinforced concrete or flexible, ductile structures like steel are best suited to withstand this soil movement. Lightweight plastic shelters often struggle against the crushing pressure of shifting clay.

10. What is the main disadvantage of a polyethylene storm shelter? The main disadvantage of polyethylene (plastic) storm shelters is their lack of mass. Because they are lightweight, they require extensive and precise anchoring with concrete to prevent floating. Additionally, they lack the fire resistance and long-term structural rigidity of steel or concrete, making them less ideal for severe weather zones like Oklahoma.